Technology

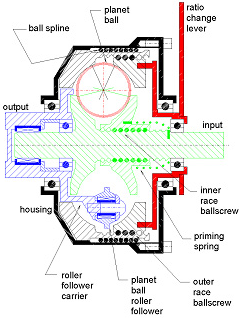

At the heart of the Orbital Mechanical Adjustable Speed Drive lies a rolling traction variator that is capable of efficiently handling both high torque and high speeds. Designed with simplicity in mind, the ASD has a small number of key components. It is essentially a variable geometry, four-point contact ball bearing with power transfer to or from the planet balls by roller followers located between the balls and mounted on a rotating carrier.

The substantial contact forces necessary to support rolling traction are contained entirely within the races of the variator assembly. Precisely the correct amount of contact force for any input torque is automatically generated by a simple helical mechanism built into the inner race assembly. This mechanism is normally a ball screw, but may also be a cam and follower arrangement. The same type of mechanism is employed in the outer race assembly to provide low-load ratio changing.

When the ratio change actuator is rotated, the axial separation between the outer race halves changes and the planet balls automatically adjust their position and contact points with the raceways. At the same time, the inner race halves automatically adjust their axial separation and contact points with the planet balls. (See Figure 2).

The ASD can be configured as fully reversible with respect to both torque and rotation directions, or it may be equipped with a built-in freewheel for uni-directional applications. Input may be to the inner race assembly with output from the roller follower carrier, as shown in the figures, or vice versa, depending on the application.

The ASD can be configured as fully reversible with respect to both torque and rotation directions, or it may be equipped with a built-in freewheel for uni-directional applications. Input may be to the inner race assembly with output from the roller follower carrier, as shown in the figures, or vice versa, depending on the application.